Tubing

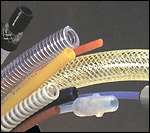

PURE GUM TUBING: A laboratory used product, pure gum tubing safely conducts acids, chemicals and gases. Pure gum tubing is also an ideal electrical insulation material for covering wires or cables in critical areas.

Major advantages of pure gum tubing: High resilience, good tensile strength, and tear resistance. Non-oil applications, great abrasion resistance, water/air and average concentration acids, bases alcohols, salts, ketones.

NEOPRENE TUBING: Neoprene is one of the best all-purpose elastomers where resistance to ozone, sunlight, oxidation and many petroleum derivatives are of prime importance. In addition to inherent heat and flame resistance, neoprene rubber will not support combustion. Good oil and petroleum based solvent resistance.

SILICONE TUBING: Excellent properties for both hot and cold temperature extremes. Excellent weathering properties, resists ozone and oxygen attack. Long service life can be expected at 200 degrees F to 400 degrees F. Extremely flexible and nontoxic for food and pharmaceutical applications. Will handle low temperature applications for -150 degrees F.

VITON TUBING: Viton tubing has good resistance to oils, fuels, lubricants, most mineral acids and to many aliphatic and aromatic hydrocarbons, such as carbon tetrachloride, toluene, benzene and xylene. Temperature range -40 degrees F to +400 degrees F.

NATURAL LATEX TUBING: Natural latex tubing is produced from liquid latex, resulting in products of highest quality. Natural latex is flexible from subzero to steam sterilization temperatures. It is "alive" snappy and vigorous. It will remaintain memory after repeated stretching or pulsating applications.

|

GOODFLEX VINYL TUBING: Goodflex tubing is a clear, flexible tubing of plasticized PVC. Its unusual combination of physical and chemical characteristics provide the industrial user with the ideal solution to a number of piping problems, involving handling of corrosive, pure or sensitive solutions. It is a FDA, USDA approved compound. Goodflex innerbraid tubing is reinforced for higher working pressures than regular tubing. |

TYGON FLEXIBLE PLASTIC TUBING

| APPLICATION Food, milk and milk products Beverages, limited food use Laboratory Surgical and hospital Flexible heavy-duty chemical Semi-rigid heavy-duty chemical Fuels and lubricants |

FORMULATION B-44-4X B-44-3 R-3603 S-50-HL R-3400 R-2400 F-4040 |

| In addition, over 200 other formulations have been developed and can be quickly produced on order. Or... we can develop a Tygon tubing formulation just for you. FOR YOUR PROTECTION... so you can be sure of getting genuine Tygon tubing and the correct formulation for your application... every foot is branded with the name "TYGON" and the formulation number. "TYGON" is a registered trademark of Norton Company. |

|

| Physical Properties (Typical) Product Characteristics |

||||||||

| Chart I Product characteristics of standard Tygon tubing formulations averaged on the basis of repeated tests made from normal production runs over a given time period. Unless otherwise noted, all tests were conducted at room temperature. |

||||||||

| B-44-4X | B-44-3 | R-1000 | R-3603 | S-50-HL | S-54-HL | R-3400 | F-4040-A | |

| Maximum Recommended Operating Temperature |

165°F (74° C) |

165°F (74° C) |

125°F (52° C) |

165°F (74° C) |

165°F (74° C) |

185°F (85° C) |

165°F (74° C) |

165°F (74° C) |

| Steam Autoclaving |

30 min. @ 15 psi (103 kPa) |

30 min. @ 15 psi (103 kPa) |

(1) | 30 min. @ 15 psi (103 kPa) |

30 min. @ 15 psi (103 kPa) |

30 min. @ 15 psi (103 kPa) |

(1) | (1) |

| Color | Clear | Clear | Clear | Clear | Clear | Clear | Black | Translucent Yellow |

| Odor | Slight | None | Slight | Slight | None | None | Slight | Slight |

| Taste | None | None | (2) | None | None | None | (2) | (2) |

| Toxicity | Nontoxic | Nontoxic | (2) | Nontoxic | Nontoxic | Nontoxic | (2) | (2) |

| Aging Characteristics |

Excellent Non-oxidizing |

Excellent Non-oxidizing |

Excellent Non-oxidizing |

Excellent Non-oxidizing |

Excellent Non-oxidizing |

Excellent Non-oxidizing |

Excellent Non-oxidizing |

Excellent Non-oxidizing |

| Chemical Resistance: | ||||||||

| Strong Acids | Good | Good | Fair | Good | Good | Good | Excellent | Fair |

| Weak Acids | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent | Good |

| Strong Alkalis | Good | Good | Poor | Good | Good | Good | Good | Poor |

| Weak Alkalis | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent | Fair |

| Organic Solvents | Poor | Poor | Poor | Poor | Poor | Poor | Poor | Fair (3) |

| (1) Restricted to chemical/industrial use only. (2) Not to be used in contact with foods, beverages, drugs. (3) Depends upon types of solvents; test in application prior to use. |

||||||||

| Chart II Physical properties of standard Tygon tubing formulations as reflected by American Society for Testing and Materials test methods. Unless otherwise noted, all tests were conducted at room temperature. Values shown were determined on 0.075-inch thick extruded strip or 0.075-inch thick molded ASTM slabs or molded ASTM durometer buttons. |

|||||||||

| ASTM Method |

B-44-4X | B-44-3 | R-1000 | R-3603 | S-50-HL | S-54-HL | R-3400 | F-4040-A | |

| Durometer Hardness Shore A, 15s |

D2240-86 | 65 | 63 | 40 | 55 | 64 | 80 | 64 | 57 |

| Tensile Strength, psi (MPa) |

D412-83 | 2100 (14.5) |

2300 (15.8) |

1200 (8.3) |

1650 (11.4) |

2000 (13.8) |

2700 (18.6) |

2250 (15.5) |

1821 (12.5) |

| Ult. Elong. % | D412-83 | 450 | 410 | 375 | 450 | 350 | 320 | 350 | 312 |

| Tensile Set, % | D412-83 | 78 | 81 | 73 | 107 | 76 | * | 66 | 50 |

| Tear Resistance, lb. f/in. (kN/m) |

D1004-66 | 200 (35) |

180 (32) |

52 (9) |

125 (22) |

165 (29) |

305 (53) |

185 (32) |

167 (29) |

| Compression Set, (5) Const. Defl. % |

D395-85 | 62 | 65 | 57 | 61 | 53 | 34 | 69 | 65 |

| Compression Set, (5) Const. Force % |

D395-85 | 47 | 45 | 52 | 47 | 41 | 63 | 48 | 40 |

| Brittle Temp. |

D746-79 | -47°F (-44° C) |

-49°F (-45° C) |

-103°F (-75° C) |

-58°F (-50° C) |

-55°F (-48° C) |

-25°F (-31° C) |

-5°F (-21° C) |

-35°F (-37° C) |

| Specific Gravity | D792-66 | 1.21 | 1.20 | 1.12. | 1.18 | 1.20 | 1.24 | 1.31 | 1.26 |

| Water Absorption, % | D570-81 | 0.15 | 0.13 | 0.3 | 0.24 | 0.14 | 0.11 | 0.19 | 0.49 |

| Flammability (1) AEB (2), inches ATB (3), secs. |

D568-77 | * * |

* * |

* * |

* * |

* * |

0.4 (1.0) |

3.5 (8.9) 5 |

4.7 (11.9) 30 |

| Burning rate, (4) in/min. (cm/min.) |

8.4 (21.3) |

6.8 (17.3) |

11.8 (30.0) |

10.6 (26.9) |

10.7 (27.2) |

* * |

* * |

* * |

|

| * Not applicable | |||||||||

| (1) Flammability of Flexible Plastics — This test applies to flexible plastics. Samples are clamped in a vertical position for testing. All samples were a nominal 0.075 inches thick. This method establishes relative burning characteristics of flexible thin plastic sheets and should not be used as a criterion for fire hazard. (2) AEB — Average extent of burning reported only if the samples tested burn less than 15 inches (38 centimeters). |

(3) ATB — Average time of burning reported only if the sample extinguishes before it burns to the 15-inch mark (38 cm). (4) Burning rate is reported for samples that burn to the bench mark, a minimum of 15 inches (38 cm). (5) Test performed at 158°F (70°C) for 22 hours. |

||||||||

TYGON VACUUM TUBING

Tygon R-3603 tubing is available with extra heavy walls for use as vacuum tubing. It will withstand full vacuum at normal room temperature and up to 27 inches (68.8 cm) of mercury vacuum at 140°F (60°C). Because of its low vapor pressure — a maximum of 3 x 10-2 mm of mercury at 140°C and 1 x 10-7 at 21°C — it will not affect liquids or gases transmitted through it. Seven sizes are available, from 3/16" (4.76 mm) ID x 9/16" (14.28 mm) OD to 1" (25.40 mm) ID x 2" (50.80 mm) OD.

TYGON "INNER-BRAIDED" TUBING

Tygon "Inner-Braided" tubing, stocked only in formulation B-44-4X, is available in nine sizes with tough Dacron* braid embedded in a diamond pattern within its wall. Its working pressures are about 4 times greater, size for size, than conventional B-44-4X. (Working pressure are figured at a conservative 1 to 4 ratio relative to burst pressures.)

The braid within the tubing wall produces a smooth outer surface, eliminating the sanitation problems of tubings with exterior braid.

Tygon "Inner-Braided" tubing retains all the advantages of visual inspection and flow control offered by reinforced tubing, and its flexibility remains unchanged from that of regular Tygon tubing.

*Reg. T.M., E.I. duPont de Nemours

WARRANTY

All recommendations and suggestions contained in our printed matter regarding end uses and methods of use are based upon the best laboratory studies, test results and experience available to us. However, as we cannot control the conditions or circumstances under which our products may be used, responsibility cannot be assumed except for freedom from defects in materials employed, uniformity of quality, and the care and skill which have been exercised in their manufacture.

All Norton products are guaranteed to fulfill the requirements of applicable Federal laws and regulations. NORTON MAKES NO OTHER WARRANTIES, EXPRESSED OR IMPLIED. Norton's responsibilities under its warranties is limited to the cost of replacing products sold.

TYGON TUBING STANDARD SIZES

| INSIDE DIAMETER | OUTSIDE DIAMETER | WALL THICKNESS | ||||||

| Inches | Milli- Meters |

Inches | Milli- Meters |

Inches | Milli- Meters |

|||

| Fraction | Decimal | Fraction | Decimal | Fraction | Decimal | |||

| 1/32 | .031 | .79 | 3/32 | .093 | 2.38 | 1/32 | .031 | .79 |

| 1/16 | .062 | 1.58 | 1/8 3/16 |

.125 .187 |

3.18 4.76 |

1/32 1/16 |

.031 .062 |

.79 1.58 |

| 3/32 | .093 | 2.38 | 5/32 7/32 |

.156 .218 |

3.96 5.55 |

1/32 1/16 |

.031 .062 |

.79 1.58 |

| 1/8 | .125 | 3.18 | 3/16 1/4 |

.187 .250 |

4.76 6.35 |

1/32 1/16 |

.031 .062 |

.79 1.58 |

| 5/32 | .156 | 3.96 | 7/32 9/32 |

.218 .281 |

5.55 7.14 |

1/32 1/16 |

.031 .062 |

.79 1.58 |

| 3/16 | .187 | 4.76 | 1/4 5/16 3/8 7/16 |

.250 .312 .375 .437 |

6.35 7.94 9.53 11.11 |

1/32 1/16 3/32 1/8 |

.031 .062 3/32 .125 |

.79 1.58 2.38 3.18 |

| 1/4 | .250 | 6.35 | 5/16 3/8 7/16 1/2 |

.312 .375 .437 .500 |

7.94 9.53 11.11 12.70 |

1/32 1/16 3/32 1/8 |

.031 .062 .093 .125 |

.79 1.58 2.38 3.18 |

| 5/16 | .312 | 7.94 | 7/16 1/2 9/16 5/8 |

.437 .500 .562 .625 |

11.11 12.70 14.29 15.88 |

1/16 3/32 1/8 5/32 |

.062 .093 .125 .156 |

1.58 2.38 3.18 3.96 |

| 3/8 | .375 | 9.53 | 1/2 9/16 5/8 |

.500 .562 .625 |

12.70 14.29 15.88 |

1/16 3/32 1/8 |

.062 .093 .125 |

1.58 2.38 3.18 |

| 7/16 | .437 | 11.11 | 9/16 5/8 11/16 |

.562 .625 .687 |

14.29 15.88 17.46 |

1/16 3/32 1/8 |

.062 .093 .125 |

1.58 2.38 3.18 |

| 1/2 | .500 | 12.70 | 5/8 11/16 3/4 13/16 |

.625 .687 .750 .812 |

15.88 17.46 19.05 20.64 |

1/16 3/32 1/8 5/32 |

.062 .093 .125 .156 |

1.58 2.38 3.18 3.96 |

| 9/16 | .562 | 14.29 | 3/4 13/16 7/8 |

.750 .812 .875 |

19.05 20.64 22.23 |

3/32 1/8 5/32 |

.093 .125 .156 |

2.38 3.18 3.96 |

| 5/8 | .625 | 15.88 | 13/16 7/8 15/16 |

.812 .875 .937 |

20.64 22.23 23.81 |

3/32 1/8 5/32 |

.093 .125 .156 |

2.38 3.18 3.96 |

| 11/16 | .687 | 17.46 | 7/8 15/16 1 |

.875 .937 1.000 |

22.23 23.81 25.40 |

3/32 1/8 5/32 |

.093 .125 .156 |

2.38 3.18 3.96 |

| 3/4 | .750 | 19.05 | 1 1-1/16 1-1/8 1-1/4 |

1.000 1.062 1.125 1.250 |

25.40 26.99 28.58 31.75 |

1/8 5/32 3/16 1/4 |

.125 .156 .187 .250 |

3.18 3.96 4.76 6.35 |

| 7/8 | .875 | 22.23 | 1-1/8 1-3/16 1-1/4 |

1.125 1.187 1.250 |

28.58 30.16 31.75 |

1/8 5/32 3/16 |

.125 .156 .187 |

3.18 3.96 4.76 |

| 1 | 1.000 | 25.40 | 1-1/4 1-5/16 1-3/8 1-1/2 |

1.250 1.312 1.375 1.500 |

31.75 33.34 34.93 38.10 |

1/8 5/32 3/16 1/4 |

.125 .156 .187 .250 |

3.18 3.96 4.76 6.35 |

| 1-1/8 | 1.125 | 28.59 | 1-3/8 1-1/2 |

1.375 1.500 |

34.93 38.10 |

1/8 3/16 |

.125 .187 |

3.18 4.76 |

| 1-1/4 | 1.250 | 31.75 | 1-1/2 1-5/8 1-3/4 |

1.500 1.625 1.750 |

38.10 41.28 44.45 |

1/8 3/16 1/4 |

.125 .187 .250 |

3.18 4.76 6.35 |

| 1-1/2 | 1.500 | 38.10 | 1-7/8 2 |

1.875 2.000 |

47.63 50.80 |

3/16 1/4 |

.187 .250 |

4.76 6.35 |

| 1-3/4 | 1.750 | 44.45 | 2-1/8 2-1/4 |

2.125 2.250 |

53.98 57.15 |

3/16 1/4 |

.187 .250 |

4.76 6.35 |

LARGE BORE TUBING

| INSIDE DIAMETER | OUTSIDE DIAMETER | WALL THICKNESS | ||||||

| Inches | Milli- Meters |

Inches | Milli- Meters |

Inches | Milli- Meters |

|||

| Fraction | Decimal | Fraction | Decimal | Fraction | Decimal | |||

| 2 | 2.000 | 50.80 | 2-3/8 2-1/2 2-3/4 3 |

2.375 2.500 2.750 3.000 |

60.33 63.50 69.85 76.20 |

3/16 1/4 3/8 1/2 |

.187 .250 .375 .500 |

4.76 6.35 9.53 12.70 |

| 2-1/4 | 2.250 | 57.15 | 2-3/4 | 2.750 | 69.85 | 1/4 | .250 | 6.35 |

| 2-1/2 | 2.500 | 63.50 | 3 3-1/4 3-1/2 |

3.000 3.250 3.500 |

76.20 82.55 88.90 |

1/4 3/8 1/2 |

.250 .375 .500 |

6.35 9.53 12.70 |

| 3 | 3.000 | 76.20 | 3-1/2 3-3/4 4 |

3.500 3.750 4.000 |

88.90 95.25 101.60 |

1/4 3/8 1/2 |

.250 .375 .500 |

6.35 9.53 12.70 |

| 4 | 4.000 | 101.60 | 5 | 5.000 | 127.00 | 1/2 | .500 | 12.70 |